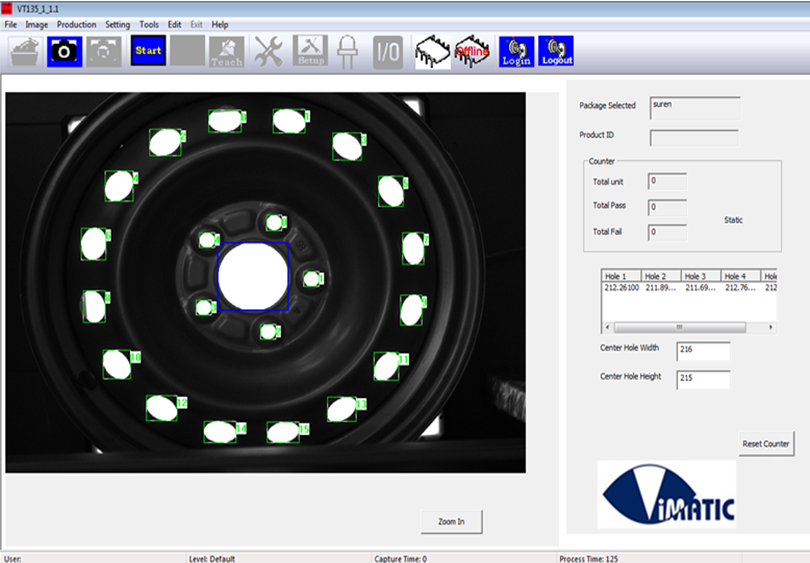

- Detection

- Benefits

- Wrong number of hole

- Hole’s diameter

- Hole’s Pitch

- Accurate and repeatable results

- Pass/fail results backed by quantitative test data

- No changeover to test different Pack formats

Is a Tyre Rim Inspection and Process monitoring system for 100% inspection of your Tyre rim and for monitoring of production process. It comes with a 2 Mega Pixel camera and it can provide rapid inspection to Tyre rim with a fast inspection time, averaging 200-250 milliseconds to inspect single Tyre rim that cover FOV 466mm at one time and produces a pass/fail result as well as quantitative, traceable data. Pass/fail result in either digital IO (other options like RS232 or TCP/IP can be achieve) will be send to machine. This system accuracy is 291um, it able to detect any defect that bigger than 600um. This system requires no tools or test parameter changes for different pack formats, single button click to load the particular package and run. VT135 Tyre Inspection system able to inspect unit on the fly or indexing, it depend on the machine’s design.

VT135 Tyre Inspection system comes with Industry PC makes it not only clean room compatible and also suitable for non-clean room environment.The intuitive and simple method make it a practical solution giving rapid feedback to production line operators.

This system support up to 4 user levels (Operator,Technician, Engineer and Admin), For Operator level, Operators simply click on the START button follow by key in the Lot Number, VT135 Tyre Inspection system will produces pass/fail result, along with a volumetric measurement reading , reject images will be save into the Lot folder that key by operator earlier for analysis purpose after production run.

Vimatic been working with several Tyre rim manufacturer to integrate VT135 Tyre Inspection system for immediate Tyre rim check and verification before end product shift out to end customer.

Our expert team delivers tailored technologies and services to streamline processes, enhance quality control, and drive operational excellence across your organization.

Vimatic Solutions is committed to ongoing R&D to build a powerful array of leading edge technologies, bringing an unique solutions.

© 2024 Vimatic Sdn Bhd 201101043721 (971841-M). All Rights Reserved. Powered by Shinjiru Technology.